О компании

GVS Filter Technology - Life Sciences

Более 40 лет опыта позволили группе GVS вырасти и стать одним из ведущих в мире производителей отлитых под давлением пластиковых фильтров и компонентов для отраслей автомобилестроения, здравоохранения, медико-биологических наук, торговли и промышленности, безопасности и бытовой техники.

Технологические инновации всегда были главным приоритетом в корпоративной повестке дня GVS, наряду с постоянной приверженностью и преданностью улучшению качества продукции и процессов посредством глобализации наших услуг на базе 15 заводов по всему миру. Вот почему GVS сегодня находится в идеальном положении, чтобы успешно решать новые и все более сложные задачи глобального рынка.

- Богатый опыт в области литья под давлением с большими и очень большими объемами (1-100 млн. шт.) и в высокоточной механической обработке, автомобильное подразделение GVS Group успешно отвечает требованиям качества и эффективности автопроизводителей. GVS сотрудничает с мировыми производителями автомобильной промышленности для достижения требуемых характеристик; от начальных этапов разработки дизайна продукта до создания прототипа, вплоть до его промышленного производства с использованием самых инновационных технологий.

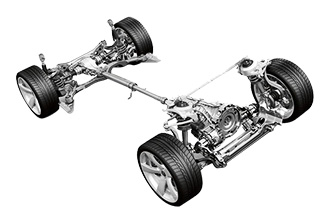

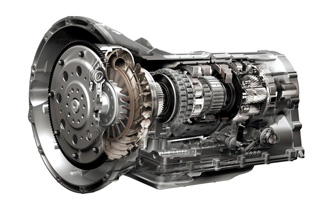

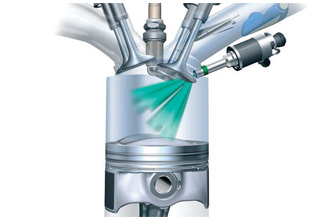

- GVS является ведущей фирмой в области фильтрации для систем ABS, систем впрыска бензина низкого и высокого давления, дизеля Common Rail высокого давления, автоматических коробок передач, дроссельных клапанов и топливных баков, вентиляционных мембран для мехатроники, датчиков и центрального процессора. GVS со своим бразильским заводом является лидером в производстве дроссельных клапанов, шестерен и валов для корпусов дросселей DBW. Каждый новый OEM-продукт разрабатывается совместно с технической командой клиента, в то время как в случае инновационных патентованных продуктов проект полностью выполняется внутри GVS.

- GVS является мировым лидером в производстве литых вентиляционных клапанов, применяемых в различных областях: от датчиков температуры, воды и масла, электронных блоков питания и управления ABS, электрических стеклоочистителей и систем освещения до инновационных электромеханических систем.

- GVS производит фильтры большого объема для топливных и дизельных систем низкого и среднего давления. Высокотехнологичные и инновационные конструктивные возможности позволяют GVS удовлетворить все потребности клиентов в системах рулевого управления, трансмиссии, ABS и тормозных фильтрах, особенно для элементов и специальных решений с фильтрами топливного бака, которые должны устанавливаться в ограниченном пространстве, что оптимизирует производительность конечного продукта.

- Применяя философию GVS и инвестируя в новые технологии, GVS стала ведущей фирмой в производстве дроссельных клапанов из алюминия, латуни и специальных сплавов. К примеру, последние инвестиции в наши предприятия в Южной Америке были направлены на разработку новой линейки компонентов для корпусов дросселей, приводных проводов и дроссельных клапанов для систем впуска воздуха.

- Хотя опыт GVS в области технологий литья под давлением на протяжении многих лет специализировался на производстве высокоточных автомобильных фильтров и компонентов, зубчатых колес и валов, сегодня мы можем решать технические задачи наших клиентов с использованием любых других пластиковых изделий.