Клапаны

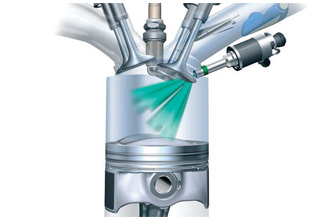

Регулируя воздушно-топливную смесь путем увеличения или уменьшения объема поступающего воздуха, дроссельные клапаны системы дроссельной заслонки могут быть механическими, электродвижущими или полностью электронными (drive-by-wire).

Клапаны могут быть механически связаны с педалью акселератора или управляться посредством комбинации педали акселератора и ECU или исключительно посредством электронных сигналов от системы управления двигателем.

Обладая более чем 40-летним опытом работы с клапанами и выпустив десятки миллионов единиц, GVS Automotive специализируется на производстве дроссельных клапанов. GVS достигли сегодняшнего уровня точности, позволяющего нам претендовать на наше мировое лидерство в области технологий и доли рынка.

Обладая более чем 40-летним опытом работы с клапанами и выпустив десятки миллионов единиц, GVS Automotive специализируется на производстве дроссельных клапанов. GVS достигли сегодняшнего уровня точности, позволяющего нам претендовать на наше мировое лидерство в области технологий и доли рынка.

Эти результаты были достигнуты благодаря уникальным технологическим предложениям, позволяющим добиться доверия клиентов и дифференциации рынка.

Например:

- Широкий диапазон доступных диаметров, от 34 мм до более 64 мм, обеспечивает существенное сокращение времени и затрат.

- Опыт GVS во внутреннем проектировании производственных систем и использование высокоточных токарных станков с ЧПУ в Италии позволяют нам поддерживать высокую точность, требуемую клапанами (+/- 4 микрона) на уровне промышленного производства.

- Чтобы гарантировать требуемые допуски, влажность и температура в производственных помещениях постоянно контролируются, чтобы сократить тепловое расширение, которое в противном случае привело бы к увеличению рабочих допусков.

- Экологически контролируемые производственные площади GVS наряду с пониманием квалифицированными работниками важности каждого отдельного микрона позволяют нам обеспечивать превосходную очистку наших продуктов.

- Благодаря многолетнему опыту GVS в области передовых технологий проектирования, методов предотвращения ошибок и систем контроля на протяжении всего производственного процесса, наша система 0 PPM постоянно работает в критически важных секторах, таких как медицина, тормозные системы ABS и топливные инжекторы.

- Знания и опыт в области свойств алюминия, латуни и специальных сплавов позволяют GVS успешно сочетать высокий уровень качества и цены для удовлетворения любых потребностей в производительности и стоимости, одновременно разрабатывая клапаны для корпусов дросселей с использованием инновационных материалов, таких как пластик, комбинации пластика и металла с зубчатым литым сектором для DBW, а также другими инновационными решениями.

- Метрологическая зона с инструментами для очень сложных рабочих программ.

- Контроль качества для клапанов может быть обеспечен опытными специалистами, работающими с GVS более 20 лет. Наши специалисты специализируются в сложной области метрологии для клапанов и механизмов. Это помогает избежать ошибок в программировании, измерении отдельных единиц, характеризующихся различными размерами углов и измерениями поверхности, которые могут легко вызвать серьезные проблемы, если не будут измерены правильно.

- Для клиентов, которым нужна конкретная работа с диаметром, GVS также предлагает постобработку, позволяющую смягчить внешние углы, что позволяет избежать компромиссов, но гарантирует лучшую и немедленную функциональность клапана за счет исключения традиционного периода адаптации водопропускных труб.

- Наконец, широкое присутствие на эталонных рынках позволяет GVS следовать за вами на каждом рынке, национализируя ваши местные проекты.