Тормозные фильтры ABS/ESP

Антиблокировочная система (ABS) позволяет предотвратить блокировку колес и занос или потерю управления при резком торможении или при торможении на мокрой или скользкой поверхности. Это добавляет значительный запас безопасности при вождении, позволяя водителю поддерживать управление рулем при попытке остановиться.

В зависимости от условий антиблокировочная система на сухом асфальте может немного увеличить тормозной путь, в то время как на мокром или скользком асфальте антиблокировочная тормозная система может уменьшить тормозной путь до 25% и более.

АБС была значительно усовершенствована, и последние версии имеют довольно много различных функций в дополнение к основной вспомогательной тормозной системе, такой как контроль тяги (TCS) и электронная система контроля устойчивости (ESP).

АБС была значительно усовершенствована, и последние версии имеют довольно много различных функций в дополнение к основной вспомогательной тормозной системе, такой как контроль тяги (TCS) и электронная система контроля устойчивости (ESP).

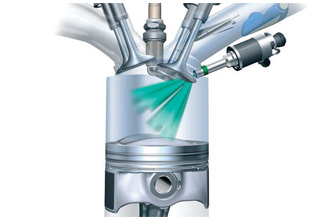

Когда любое из вращающихся колес начинает замедляться с большей скоростью, чем другие, система АБС, которая непрерывно контролирует скорость вращения колес во время торможения с помощью датчиков, реагирует кратковременным снижением давления в тормозном контуре через электромагнитные клапаны с электроприводом. Это уменьшает тормозное усилие на колесе, позволяя ему восстановить сцепление с дорогой и не позволяя ему заблокироваться, тем самым приводя его в соответствие с другими.

GVS разработала передовые фильтровальные решения для жидкости гидравлического контура АБС-ESC/P, предотвращая загрязнение датчиков скорости вращения колес металлической пылью и сбои в обнаружении проскальзывания колеса.

Наша специальная технология производства основана на инновационных решениях. С произ-водством очень больших объёмов персонализированных фильтров и автоматическими пресс-формами, производящими до 50 миллионов фильтров без дефектов в год, это, безусловно, эталон для каждой новой системы АБС-ESC/P, от стадии разработки проекта до готового продукта.

Производство в чистых помещениях класса 100,000 гарантирует уровень чистоты в соответствии с требуемыми стандартами, где присутствие частиц недопустимо. Стандартные фильтрующие материалы из PE, PA и стали удовлетворяют всем производственным спецификациям, в то время как исследования и технологические разработки позволяют получать новые решения, которые улучшают эксплуатационные характеристики продуктов и снижают себестоимость единицы продукции.

GVS всегда верила в применение политики сильных технологических инвестиций, и сегодня это означает увеличение объемов производства в среднем на 25% в год.